Specimen preparation for microstructural examination involves a series of operations, the ease and success of each depends on the preceding step. The first cut impacts all subsequent steps and the impact can be quite detrimental if too much damage is induced during sectioning.

Abrasive and Precision Cutter

The IsoMet High Speed Pro has a blade motor power of 2kW, which is the strongest motor on the market. This motor power ensures the blade will minimize the deformation of the sample surface, saving you time later in the material preparation process. Reduce the cut time without impacting the surface quality.

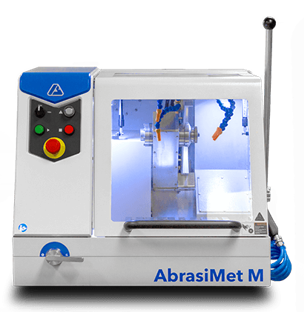

The AbrasiMet M is a benchtop manual cutting machine for 10in [254mm] and 12in [305mm] blades that provides consistent sectioning results. The sliding door allows easy access to the cutting chamber to quickly position samples for cutting. A powerful motor and ergonomic cutting arm provide a smooth and efficient cutting motion.

The AbrasiMet™ XL Pro is a floor standing automatic abrasive cutting machine for 14in [356mm] to 18in [457mm] blades that provides consistent and repeatable cut quality for larger diameter samples. An intuitive user interface with programmable methods allows users to create and save multiple sectioning programs for quick access. The machine’s large chamber and powerful motor allow for fast sectioning of large workpieces with ease. The AbrasiMet XL Pro is the ideal machine for use in demanding environments.

Accessories and Consumables

An important part of sectioning is proper wheel or blade selection. Like everything in materials preparation, there are trade-offs, but through evaluation of your needs and processes, the best abrasive wheel or precision blade for your application can be selected.