When quick and informed decisions need to be made to ensure the profitability of a transaction in precious metals trading or make sure jewellery is free of toxic substance, the use of X-ray Fluorescence Spectroscopy (XRF) can be invaluable.

Thermo ScientificTM NitonTM portable XRF desktop and handheld analysers provide pawn shops, cash-for-gold businesses, jewellers, recyclers and refineries fast, reliable and accurate results for

- Determination of karat grade and fineness

- Analysis of all precious metals including gold, platinum, palladium, silver, iridium, rhodium, ruthenium

- Analysis of alloying elements like copper, zinc, nickel, etc.

- Analysis of toxic elements like cadmium or lead etc.

- Detection of gold plating presence with the patented AuDITTM technology

Unlike traditional test methods, all precious metals and alloys, in various size and shapes are tested completely non-destructively.

Niton™ DXL

The Niton™ DXL analyzer, equipped with Thermo Scientific™ AuDIT™ gold-plating detection technology, has been specifically designed for countertop use in retail settings, delivering quick and reliable results for metal analysis and gold testing with a simple push of a button.

Just a few seconds is all it takes to measure the exact precious metal content in jewellery, coins, and other valuable products using the Niton DXL Precious Metal Analyzer.

- Standard analytical range: 21 elements including all precious metals.

- Non-destructive analysis with near instantaneous results.

- Exceptionally fast, easy to use – see results in seconds on a bright, touchscreen colour display.

- No harsh chemicals or acids that can burn your fingers, ruin clothing, and damage countertops.

- Easier, faster, more accurate than nitric acid test methods.

- Faster, more comprehensive analysis than fire assay, with comparable accuracy.

- Compact, elegant, ergonomic design for countertop placement in retail environments.

- Measure the content of all gold and precious metals without manually changing the calibration.

- Precisely determine the presence and concentration of other trace alloying elements and dangerous heavy elements, which could impact valuation and future refining needs.

- Built-in CCD camera makes precise sample positioning effortless.

- Optional small‑spot focus allows isolation and testing of small components.

Jewellery creation requires very high quality, precision, performance and reliability, the basic principles that underpin the conception and design of machines used by the company.

Orotig provides a complete line of products for casting, welding, marking and cutting of all precious metals. It is currently the gold standard for the production of jewellery, with world renown quality and reliability.

The company’s extensive offer meets all client requirements, from handcrafted to industrial production.

Welding

The laser welding process exploits the extremely high density of energy produced by Nd:YAG sources which, delivered over a very short period of time, allows to rapidly melt the metal, thus reducing the demand for heat to a minimum. The welding points generated are smaller, cleaner and deeper than those which can be obtained using traditional welding techniques, besides also featuring better quality standards.

The benefits of laser welding include

- extraordinary cleaning and high precision

- processing speed

- minimum contribution of heat

- excellent welding aesthetics

- adjustment of the deep penetration

- very high mechanical resistance

Orotig is world leader in the production of laser welders with solid state source, which emit pulsed light.

This type of welding is extremely efficient on all metals and particularly on carbon steel, stainless steel, aluminium alloys, titanium, nickel, cast iron, gold, silver, platinum, palladium, copper, bronze and brass.

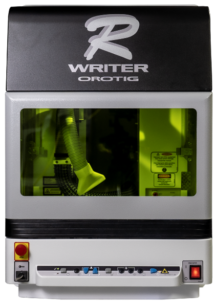

Marking and Cutting

The laser marking proposed by Orotig can be defined “Total Laser Fibre” because all important components, such as active fibre, fibre combiners and diodes, work jointly with the main fibre; hence, they are totally immune to typical problems, such as the possible misalignment of optical components, which often causes a loss of power.

This system of joined optical components allows the equipment to operate for up to 30,000 hours without requiring any intervention to align the integrated components.

Extremely compact, efficient and practically not requiring any maintenance, “fibre source” laser features the quality and precision of the beam, which is higher than the “crystal” laser. As a result of these qualities, the laser generated by fibre sources is used for cutting and marking processes, which are highly precise and complex applications.

Casting

Today, as thirty years ago, Orotig casting machines are the best solution for the micro-casting of titanium. Though its use in the dental sector has diminished to the benefit of milling machines, its dissemination has found new impetus in the jewellery sector.

In fact, in recent years an increasing number of brands are discovering the surprising quality of titanium and the extraordinary compatibility with gold to create the jewels.

The micro-casting system created by Orotig guarantees excellent results for platinum processing.

For the jewellery industry and in cooperation with other organisations in the sector, Orotig has once again developed a revolutionary system for the fusion of precious metals capable of reducing to a minimum the discards, and of thus avoiding losses of material and of pointless re-processing.

Milling

Conceived and created for the most demanding applications in the dental sector, Orotig’s milling system meets the highest working quality standards.

Orotig proposes CNC systems with 5 axes places continuously, designed for high precision milling of 3D details especially for use in the dental industry. Rapid and precise handling, with screws and ball bearing guides without any margin, are the machine’s basic features.

The machine is capable of processing metals, and also waxes, plastics, zirconium, ceramic and metals.