Ultrasonic Cleaning

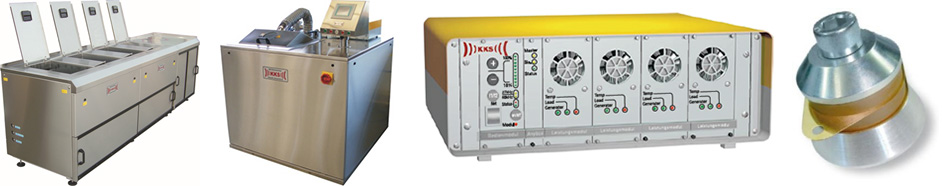

Ultrasonic cleaning is a very effective and gentle process for intensively cleaning materials of all types, as well as finely structured, porous, open-pored surfaces and very complex geometries, in a very short time, without additional manual effort and without damage.

The range of applications extends from the smallest components for microelectronics and optics, through medical implants, to bulky parts for the automotive industry.

Mechanical Surface Refinement – Wet Blasting

KKS wet blasting units impress with their high blasting performance and short blasting times – because cost reduction and time savings are important success factors and offer significant competitive advantages.

Surface quality are easily reproducible surface with KKS wet blasting units.

Application range:

- Texturing, mattening, roughening

- Removal of coatings

- Cleaning

- Densification of boundary areas of metal components to enhance their fatigue-strength

Chemical surface refinement

For many years, chemical surface refinement has been used successfully in the medical and general industry. Processes such as passivation, pickling and etching optimise surface characteristics. KKS systems for chemical surface refinement guarantee a simple and efficient way of handling with excellent and reproducible results.

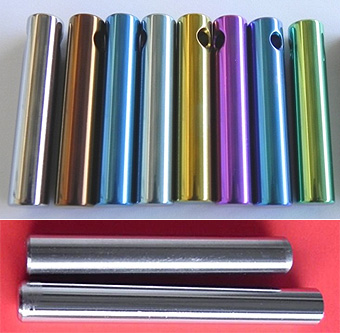

Electrochemical surface refinement

Electrochemical surface refinement can be used in many different application. Whenever there is an increase demand on the function and appearance of metallic surfaces, electrochemical processes such as electrolytic polishing and anodising are the methods to choice. KKS systems for electrochemical surface refinement guarantee a simple and efficient way of handling with excellent and reproducible results.